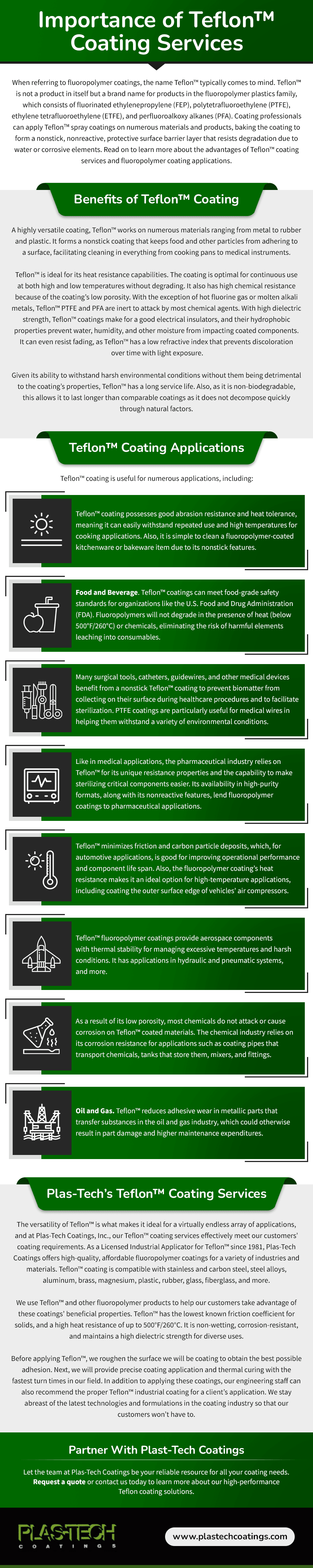

When referring to fluoropolymer coatings, the name Teflon™ typically comes to mind. Teflon™ is not a product in itself but a brand name for products in the fluoropolymer plastics family, which consists of fluorinated ethylenepropylene (FEP), polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and perfluoroalkoxy alkanes (PFA). Coating professionals can apply Teflon spray coatings on numerous materials and products, baking the coating to form a nonstick, nonreactive, protective surface barrier layer that resists degradation due to water or corrosive elements. Read on to learn more about the advantages of Teflon™ coating services and fluoropolymer coating applications.

Benefits of Teflon™ Coating

A highly versatile coating, Teflon™ works on numerous materials ranging from metal to rubber and plastic. It forms a nonstick coating that keeps food and other particles from adhering to a surface, facilitating cleaning in everything from cooking pans to medical instruments.

Teflon™ is ideal for its heat resistance capabilities. The coating is optimal for continuous use at both high and low temperatures without degrading. It also has high chemical resistance because of the coating’s low porosity. With the exception of hot fluorine gas or molten alkali metals, Teflon™ PTFE and PFA are inert to attack by most chemical agents. With high dielectric strength, Teflon™ coatings make for a good electrical insulator, and its hydrophobic properties prevent water, humidity, and other moisture from impacting coated components. It can even resist fading, as Teflon™ has a low refractive index that prevents discoloration over time with light exposure.

Given its ability to withstand harsh environmental conditions without them being detrimental to the coating’s properties, Teflon™ has a long service life. Also, as it is non-biodegradable, this allows it to last longer than comparable coatings as it does not decompose quickly through natural factors.

Teflon™ Coating Applications

Teflon™ coating is useful for numerous applications, including:

- Teflon™ coating possesses good abrasion resistance and heat tolerance, meaning it can easily withstand repeated use and high temperatures for cooking applications. Also, it is simple to clean a fluoropolymer-coated kitchenware or bakeware item due to its nonstick features.

- Food and beverage. Teflon™ coatings can meet food-grade safety standards for organizations like the U.S. Food and Drug Administration (FDA). Fluoropolymers will not degrade in the presence of heat (below 500oF/260oC) or chemicals, eliminating the risk of harmful elements leaching into consumables.

- Many surgical tools, catheters, guidewires, and other medical devices benefit from a nonstick Teflon™ coating to prevent biomatter from collecting on their surface during healthcare procedures and to facilitate sterilization. PTFE coatings are particularly useful for medical wires in helping them withstand a variety of environmental conditions.

- Like in medical applications, the pharmaceutical industry relies on Teflon™ for its unique resistance properties and the capability to make sterilizing critical components easier. Its availability in high-purity formats, along with its nonreactive features, lend fluoropolymer coatings to pharmaceutical applications.

- Teflon™ minimizes friction and carbon particle deposits, which, for automotive applications, is good for improving operational performance and component life span. Also, the fluoropolymer coating’s heat resistance makes it an ideal option for high-temperature applications, including coating the outer surface edge of vehicles’ air compressors.

- Teflon™ fluoropolymer coatings provide aerospace components with thermal stability for managing excessive temperatures and harsh conditions. It has applications in hydraulic and pneumatic systems, and more.

- As a result of its low porosity, most chemicals do not attack or cause corrosion on Teflon™ coated materials. The chemical industry relies on its corrosion resistance for applications such as coating pipes that transport chemicals, tanks that store them, mixers, and fittings.

- Oil and gas. Teflon™ reduces adhesive wear in metallic parts that transfer substances in the oil and gas industry, which could otherwise result in part damage and higher maintenance expenditures.

Plas-Tech’s Teflon™ Coating Services

The versatility of Teflon™ is what makes it ideal for a virtually endless array of applications, and at Plas-Tech Coatings, Inc., our Teflon™ coating services effectively meet our customers’ coating requirements. As a Licensed Industrial Applicator for Teflon™ since 1981, Plas-Tech Coatings offers high-quality, affordable fluoropolymer coatings for a variety of industries and materials. Teflon™ coating is compatible with stainless and carbon steel, steel alloys, aluminum, brass, magnesium, plastic, rubber, glass, fiberglass, and more.

We use Teflon™ and other fluoropolymer products to help our customers take advantage of these coatings’ beneficial properties. Teflon™ has the lowest known friction coefficient for solids, and a high heat resistance of up to 500° F/260oC. It is non-wetting, corrosive-resistant, and maintains a high dielectric strength for diverse uses.

Before applying Teflon™, we roughen the surface we will be coating to obtain the best possible adhesion. Next, we will provide precise coating application and thermal curing with the fastest turn times in our field. In addition to applying these coatings, our engineering staff can also recommend the proper Teflon™ industrial coating for a client’s application. We stay abreast of the latest technologies and formulations in the coating industry so that our customers won’t have to.

Partner With Plast-Tech Coatings

Let the team at Plas-Tech Coatings be your reliable resource for all your coating needs. Request a quote or contact us today to learn more about our high-performance Teflon coating solutions.