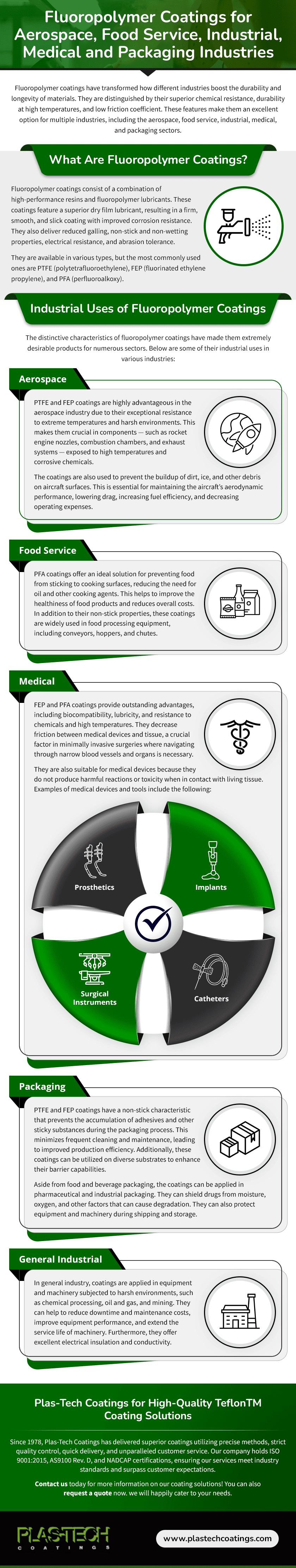

Fluoropolymer coatings have transformed how different industries boost the durability and longevity of materials. They are distinguished by their superior chemical resistance, durability at high temperatures, and low friction coefficient. These features make them an excellent option for multiple industries, including the aerospace, food service, industrial, medical, and packaging sectors.

In this article, we will explore the diverse applications of this coating type. We will also examine the benefits that make it the go-to material coating.

What Are Fluoropolymer Coatings?

Fluoropolymer coatings consist of a combination of high-performance resins and fluoropolymer lubricants. These coatings feature a superior dry film lubricant, resulting in a firm, smooth, and slick coating with improved corrosion resistance. They also deliver reduced galling, non-stick and non-wetting properties, electrical resistance, and abrasion tolerance.

They are available in various types, but the most commonly used ones are PTFE (polytetrafluoroethylene), FEP (fluorinated ethylene propylene), and PFA (perfluoroalkoxy).

Industrial Uses of Fluoropolymer Coatings

The distinctive characteristics of fluoropolymer coatings have made them extremely desirable products for numerous sectors. Below are some of their industrial uses in various industries:

Aerospace

PTFE and FEP coatings are highly advantageous in the aerospace industry due to their exceptional resistance to extreme temperatures and harsh environments. This makes them crucial in components — such as rocket engine nozzles, combustion chambers, and exhaust systems — exposed to high temperatures and corrosive chemicals.

The coatings are also used to prevent the buildup of dirt, ice, and other debris on aircraft surfaces. This is essential for maintaining the aircraft’s aerodynamic performance, lowering drag, increasing fuel efficiency, and decreasing operating expenses.

Food Service

PFA coatings offer an ideal solution for preventing food from sticking to cooking surfaces, reducing the need for oil and other cooking agents. This helps to improve the healthiness of food products and reduces overall costs. In addition to their non-stick properties, these coatings are widely used in food processing equipment, including conveyors, hoppers, and chutes.

The coatings are also used in food packaging applications, where they act as an effective barrier against moisture, oxygen, and other gases that can spoil food products. This characteristic enables the extension of the shelf life of products, reduces food waste, and helps to maintain quality and freshness.

Medical

FEP and PFA coatings provide outstanding advantages, including biocompatibility, lubricity, and resistance to chemicals and high temperatures. They decrease friction between medical devices and tissue, a crucial factor in minimally invasive surgeries where navigating through narrow blood vessels and organs is necessary.

They are also suitable for medical devices because they do not produce harmful reactions or toxicity when in contact with living tissue. Examples of medical devices and tools include the following:

- Catheters

- Implants

- Medical tubing

- Needles

- Prosthetics

- Stents

- Surgical instruments

Packaging

PTFE coatings have a non-stick characteristic that prevents the accumulation of adhesives and other sticky substances during the packaging process. This minimizes frequent cleaning and maintenance, leading to improved production efficiency. Additionally, these coatings can be utilized on diverse substrates to enhance their barrier capabilities.

Aside from food and beverage packaging, the coatings can be applied in pharmaceutical and industrial packaging. They can shield drugs from moisture, oxygen, and other factors that can cause degradation. They can also protect equipment and machinery during shipping and storage.

General Industrial

In general industry, coatings are applied in equipment and machinery subjected to harsh environments, such as chemical processing, oil and gas, and mining. They can help to reduce downtime and maintenance costs, improve equipment performance, and extend the service life of machinery. Furthermore, they offer excellent electrical insulation and conductivity.

Plas-Tech Coatings for High-Quality TeflonTM Coating Solutions

Since 1978, Plas-Tech Coatings has delivered superior coatings utilizing precise methods, strict quality control, quick delivery, and unparalleled customer service. Our company holds ISO 9001:2015, AS9100 Rev. D, and NADCAP certifications, ensuring our services meet industry standards and surpass customer expectations.

Contact us today for more information on our coating solutions! You can also request a quote now; we will happily cater to your needs.