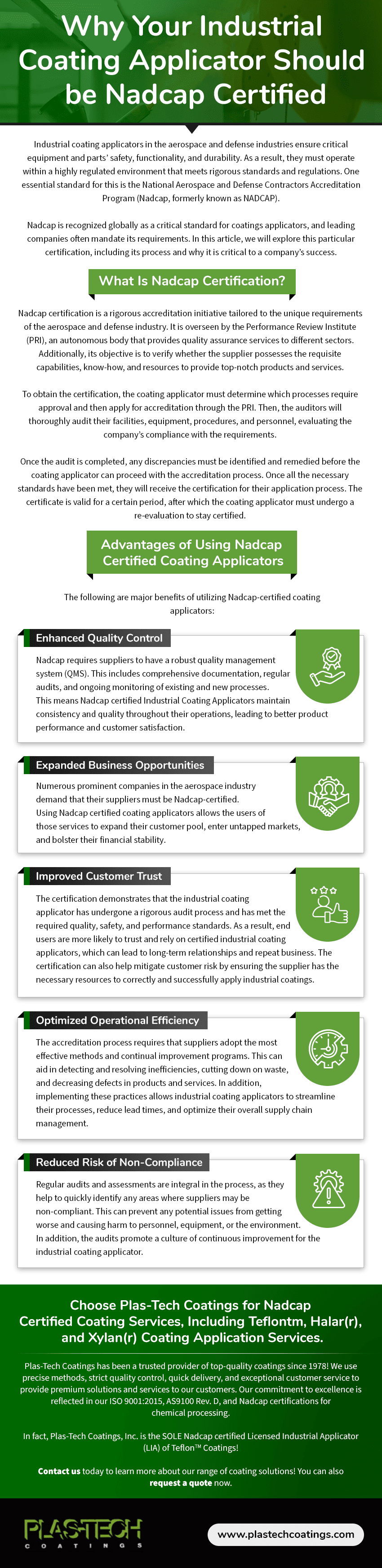

Industrial coating applicators in the aerospace and defense industries ensure critical equipment and parts’ safety, functionality, and durability. As a result, they must operate within a highly regulated environment that meets rigorous standards and regulations. One essential standard for this is the National Aerospace and Defense Contractors Accreditation Program (Nadcap, formerly known as NADCAP).

Nadcap is recognized globally as a critical standard for coatings applicators, and leading companies often mandate its requirements. In this article, we will explore this particular certification, including its process and why it is critical to a company’s success.

What Is Nadcap Certification?

Nadcap certification is a rigorous accreditation initiative tailored to the unique requirements of the aerospace and defense industry. It is overseen by the Performance Review Institute (PRI), an autonomous body that provides quality assurance services to different sectors. Additionally, its objective is to verify whether the supplier possesses the requisite capabilities, know-how, and resources to provide top-notch products and services.

To obtain the certification, the coating applicator must determine which processes require approval and then apply for accreditation through the PRI. Then, the auditors will thoroughly audit their facilities, equipment, procedures, and personnel, evaluating the company’s compliance with the requirements.

Once the audit is completed, any discrepancies must be identified and remedied before the coating applicator can proceed with the accreditation process. Once all the necessary standards have been met, they will receive the certification for their application process. The certificate is valid for a certain period, after which the coating applicator must undergo a re-evaluation to stay certified.

Advantages of Using Nadcap Certified Coating Applicators

The following are major benefits of utilizing Nadcap-certified coating applicators:

Enhanced Quality Control

Nadcap requires suppliers to have a robust quality management system (QMS). This includes comprehensive documentation, regular audits, and ongoing monitoring of existing and new processes. This means Nadcap certified Industrial Coating Applicators maintain consistency and quality throughout their operations, leading to better product performance and customer satisfaction.

Expanded Business Opportunities

Numerous prominent companies in the aerospace industry demand that their suppliers must be Nadcap-certified. Using Nadcap certified coating applicators allows the users of those services to expand their customer pool, enter untapped markets, and bolster their financial stability.

Improved Customer Trust

The certification demonstrates that the industrial coating applicator has undergone a rigorous audit process and has met the required quality, safety, and performance standards. As a result, end users are more likely to trust and rely on certified industrial coating applicators, which can lead to long-term relationships and repeat business. The certification can also help mitigate customer risk by ensuring the supplier has the necessary resources to correctly and successfully apply industrial coatings.

Optimized Operational Efficiency

The accreditation process requires that suppliers adopt the most effective methods and continual improvement programs. This can aid in detecting and resolving inefficiencies, cutting down on waste, and decreasing defects in products and services. In addition, implementing these practices allows industrial coating applicators to streamline their processes, reduce lead times, and optimize their overall supply chain management.

Reduced Risk of Non-Compliance

Regular audits and assessments are integral in the process, as they help to quickly identify any areas where suppliers may be non-compliant. This can prevent any potential issues from getting worse and causing harm to personnel, equipment, or the environment. In addition, the audits promote a culture of continuous improvement for the industrial coating applicator.

Choose Plas-Tech Coatings for Nadcap Certified Coating Services, Including Teflontm, Halar(r), and Xylan(r) Coating Application Services.

Plas-Tech Coatings has been a trusted provider of top-quality coatings since 1978! We use precise methods, strict quality control, quick delivery, and exceptional customer service to provide premium solutions and services to our customers. Our commitment to excellence is reflected in our ISO 9001:2015, AS9100 Rev. D, and Nadcap certifications for chemical processing.

In fact, Plas-Tech Coatings, Inc. is the SOLE Nadcap certified Licensed Industrial Applicator (LIA) of Teflontm Coatings!

Contact us today to learn more about our range of coating solutions! You can also request a quote now.